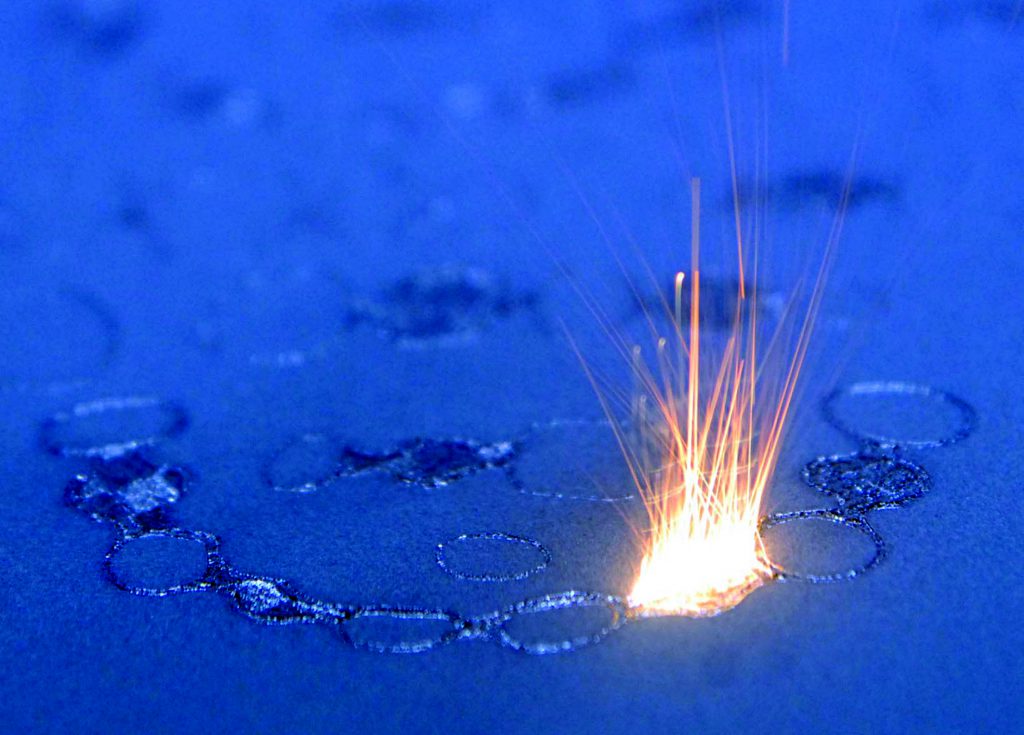

Metal 3D printing technology, with its unique manufacturing capabilities, is revolutionizing the modern manufacturing industry. However, this technology is also accompanied by potential hazards in the process of using lasers to melt metal powders – the generation of dust. If these fumes are not handled promptly and effectively, they will not only reduce printing accuracy and workpiece quality, but may also cause equipment damage by covering the protective mirror of the laser system.

Hazards of smoke and dust

The smoke generated during the melting of metal powder contains unreacted metal powder and solidified large particles, which have extremely high chemical activity and residual energy. When these smoke come into contact with the outside air, they are very likely to cause combustion or explosion, posing a serious safety hazard.

Necessity of atmosphere circulation filtration system

In order to effectively control the smoke hazards in the metal 3D printing process, it is particularly necessary to use an atmosphere circulation filtration system. The system uses a large-volume circulation fan to generate negative pressure, quickly remove the smoke, and isolate it through a filter device, and then return the clean gas to the molding cavity to form a stable circulation process.

Filtration System Challenges

During this cycle, impurities of different particle sizes need to be effectively filtered out, including large particles, powders and smoke. However, the filtration devices currently on the market are often of a single design, and most only use a primary circular filter element, which has many internal folds and poor backwashing effect, resulting in a short filter element life and the need for frequent replacement.

Wansheng Intelligent Manufacturing’s innovative solutions

Wansheng Intelligent Manufacturing, relying on years of in-depth research on customer sites and understanding of customer needs, has launched a permanent filter element PPS dust removal system. The system adopts a modular multi-stage dust removal design, and through multiple designs such as process improvement of the filter element, it significantly reduces the frequency of filter element replacement and extends its service life.

Wansheng Intelligent Manufacturing not only solves customers’ pain points, but also adheres to the spirit of craftsmanship, takes a meticulous attitude and independent innovation as the core, providing customers with safe, efficient, economical and convenient dust removal solutions.